Tesla Optimus Just Leveled Up:

The New Gen 3 Hands and Why This Changes Everything

Posted by Robo-Rx | November 23, 2025

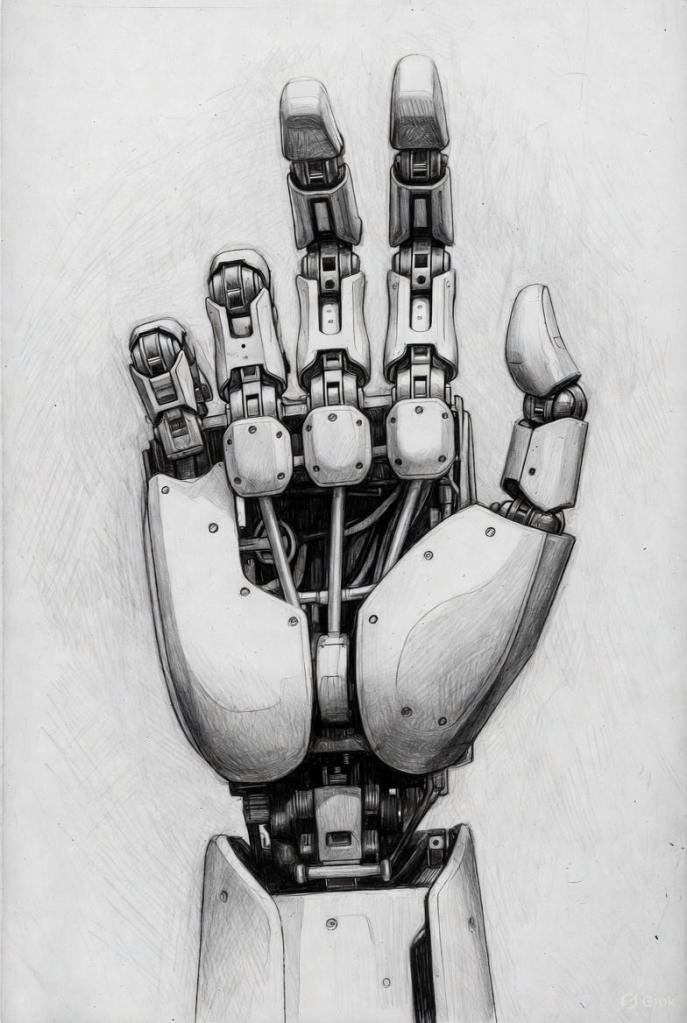

If you thought the Optimus Gen 2 hand was impressive, buckle up. Tesla just dropped details on the Gen 3 hand that move the goalposts for what a mass-produced humanoid robot can actually do in the real world.

The Big Jump: From 11 DoF → 25 DoF Per Hand/Arm Combo

The new Gen 3 hand delivers:

- 22 degrees of freedom in the hand itself (almost double the previous 11 DoF)

- An additional 3 DoF in the wrist/forearm area

- ≈100 total actuators across both arms and hands (roughly 50 per side)

In plain English: these hands are now capable of true human-level (and in some cases super-human) dexterity.

Watch the mid-November gait video again and you’ll notice something subtle but huge — the arms swing naturally and the fingers are already articulating in ways that look eerily alive. That’s not just better walking; it’s the foundation for useful work.

Real-World Tasks This Actually Unlocks

- Picking up eggs, keys, or a single screw without crushing or dropping them

- Threading a needle or tying shoelaces (yes, Tesla has shown both in internal demos)

- Precise electrical assembly — plugging connectors, stripping wire, torqueing fasteners to spec

- Surgical-level manipulation (Elon has repeatedly said Optimus will eventually outperform the best human surgeons)

For anyone who’s ever tried to program a traditional 6-axis industrial robot to do any of the above, you know this is a massive leap.

The Cost Story (and Why It Matters to You)

Right now, a single Gen 3 hand assembly costs Tesla somewhere between $30,000 and $80,000 to build. That’s the honest reality of cutting-edge actuators, sensors, and custom gearing.

The target? Under $10,000 per hand at scale.

When that happens (and Tesla has a track record of crushing cost curves once volume kicks in), the entire economics of in-home and small-business robotics flips overnight. A $20–30K Optimus becomes realistic, and the cost of a repair or hand replacement becomes something a normal household or small shop can actually budget for.

What This Means for Future Optimus Owners (and for Robo-Rx)

- Repair complexity just went up — more actuators, more tendons, more sensors = specialized diagnostics and service.

- Training demand will explode — end users and technicians will need to understand the new hand architecture, failure modes, and calibration procedures.

- Upgrade paths are coming — Tesla has already hinted that earlier Gen 2 bots may be field-upgradable to Gen 3 hands.

At Robo-Rx we’re already reverse-engineering the actuator layouts, building test fixtures, and writing the service manuals that don’t exist yet. When the first thousand Gen 3 Optimus units leave Fremont in 2026, we plan to be the shop that can swap a damaged hand in hours instead of weeks — and teach you (or your staff) how to keep them running at peak performance.